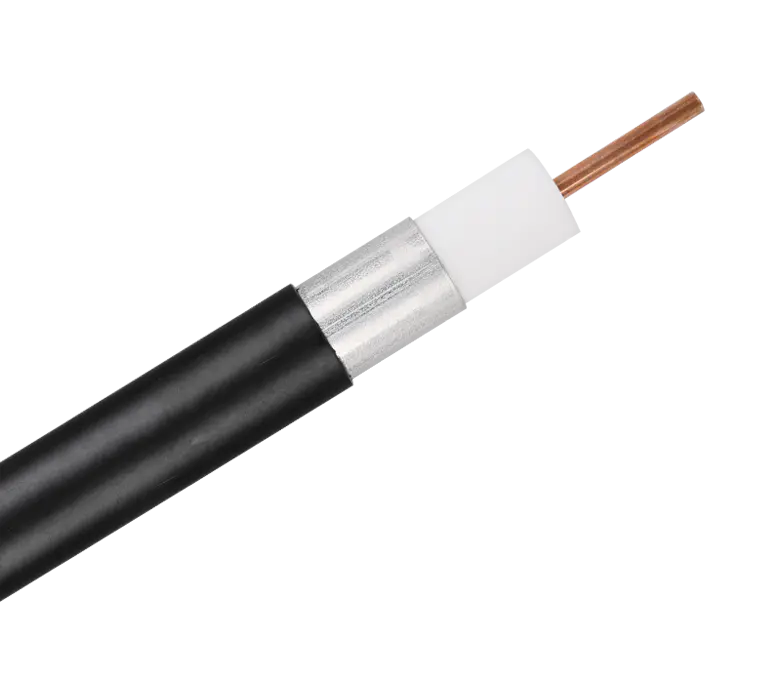

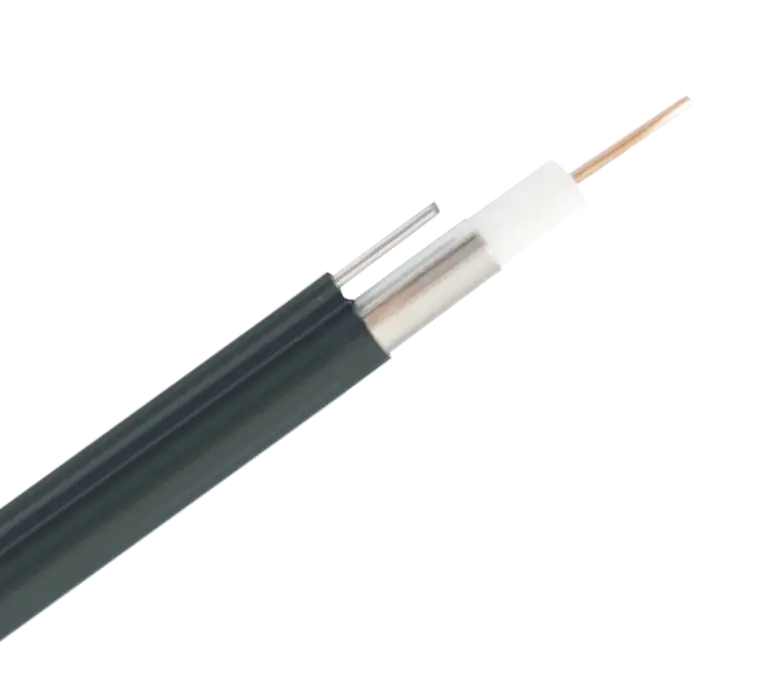

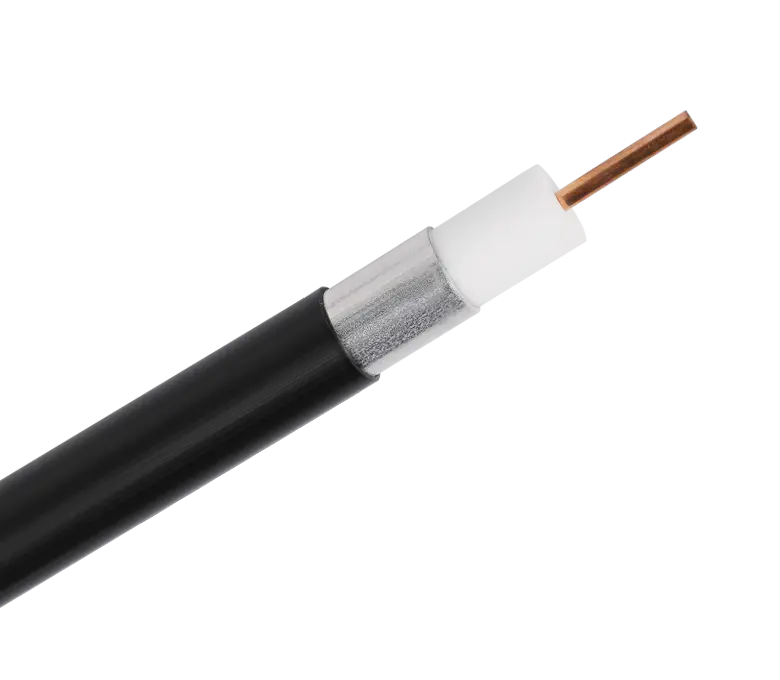

Physical Durability: Industrial bus cables are designed to withstand physical stress, including bending, twisting, and crushing, without compromising their functionality. They are often constructed with tough outer jackets and reinforcement layers to protect the inner conductors.

Chemical Resistance: Many industrial settings involve exposure to chemicals and oils. Robust industrial bus cables are resistant to a wide range of chemicals, preventing corrosion and degradation of the cable materials.

Temperature Tolerance: Industrial environments can experience extreme temperatures, from very hot to very cold. These cables are designed to operate reliably across a wide temperature range, ensuring they continue to function in harsh conditions.

Moisture and Environmental Protection: Industrial bus cables are often rated for ingress protection (IP) to shield against dust and moisture. This protection is crucial for applications where exposure to water, humidity, or contaminants is a concern.

Abrasion Resistance: In environments where cables are subjected to abrasion, such as when routed through conduit or dragged across rough surfaces, robust cables are equipped with abrasion-resistant materials to prevent damage.

Impact Resistance: Cables can be accidentally struck or bumped in industrial settings. Robust cables are designed to withstand moderate impact without causing internal damage or signal interference.

Electromagnetic Interference (EMI) Shielding: Industrial bus cables incorporate shielding to protect against electromagnetic interference from nearby machinery and equipment. This shielding ensures that the signals transmitted through the cable remain stable and unaffected by external electromagnetic sources.

Vibration Tolerance: In environments with heavy machinery or equipment in operation, cables may be exposed to constant vibrations. Robust industrial bus cables are engineered to handle such vibrations without signal degradation.

UV Resistance: When exposed to outdoor or sunlight-rich environments, some industrial bus cables are UV-resistant, preventing damage from prolonged exposure to ultraviolet radiation.

Flame and Fire Resistance: In certain applications, such as in the automotive or aerospace industries, cables may need to meet specific fire safety standards. Robust industrial cables can be designed to be flame-retardant or fire-resistant.

Corrosion Resistance: For applications in marine or offshore environments, where exposure to saltwater and corrosion is a concern, industrial bus cables can be designed with materials that resist corrosion.

Longevity: Robust industrial bus cables are built to have a longer service life, reducing the need for frequent replacements and maintenance.

In summary, the robustness of industrial bus cables is reflected in their ability to withstand physical stress, resist environmental factors like chemicals and temperature extremes, and maintain reliable signal transmission in challenging industrial conditions. These characteristics ensure that they can continue to operate effectively and provide stable communication in critical applications.

浙公网安备33018502001191号

浙公网安备33018502001191号