Color Printing Packaging Line, Imported New High-end Printing Equipment

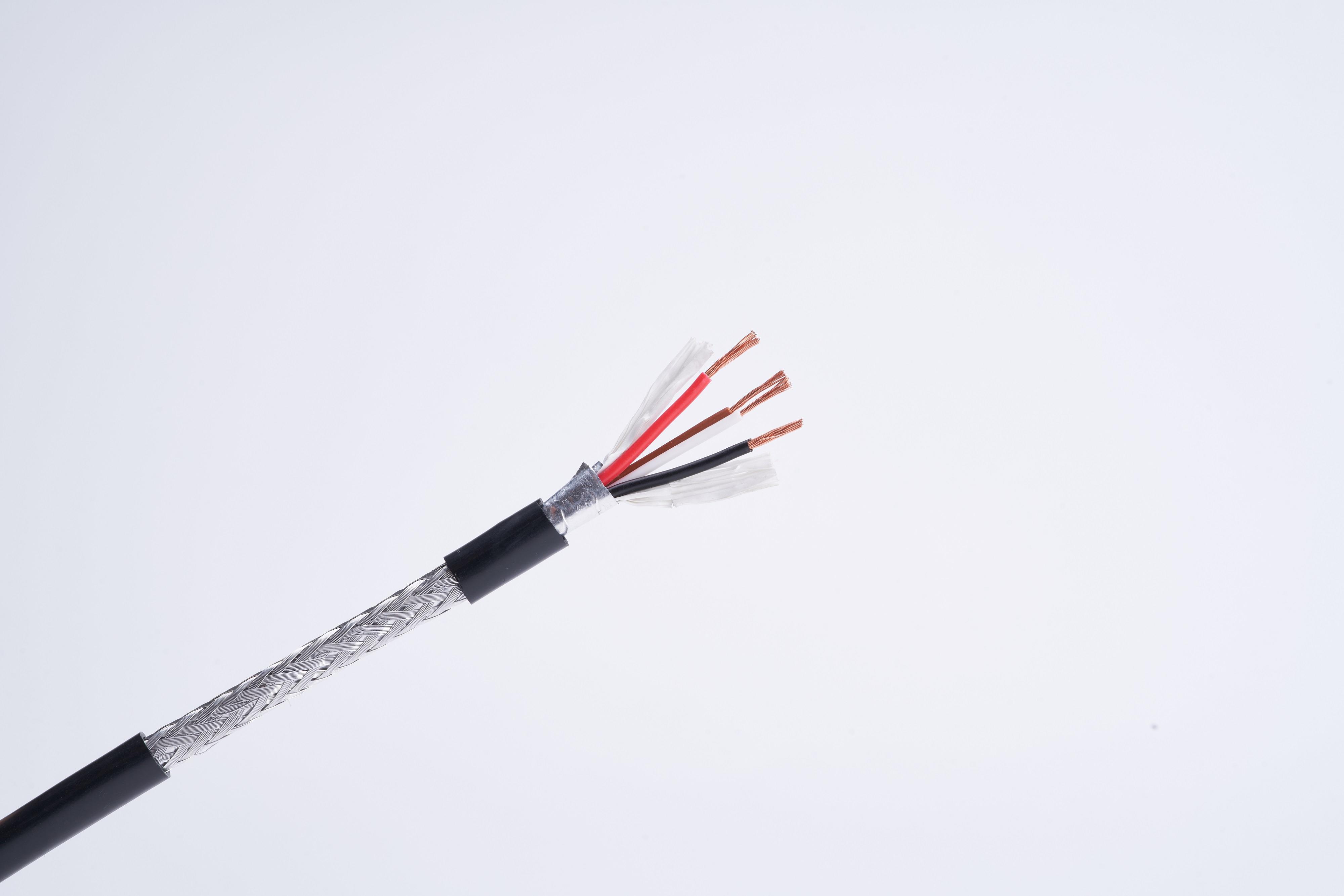

SP16-2-65STR Speaker Cable Distribution Cable

Using to connect power amplifier and loudspeaker equipment, broadcast system to transmit audio frequ...

More details

Using to connect power amplifier and loudspeaker equipment, broadcast system to transmit audio frequ...

More details

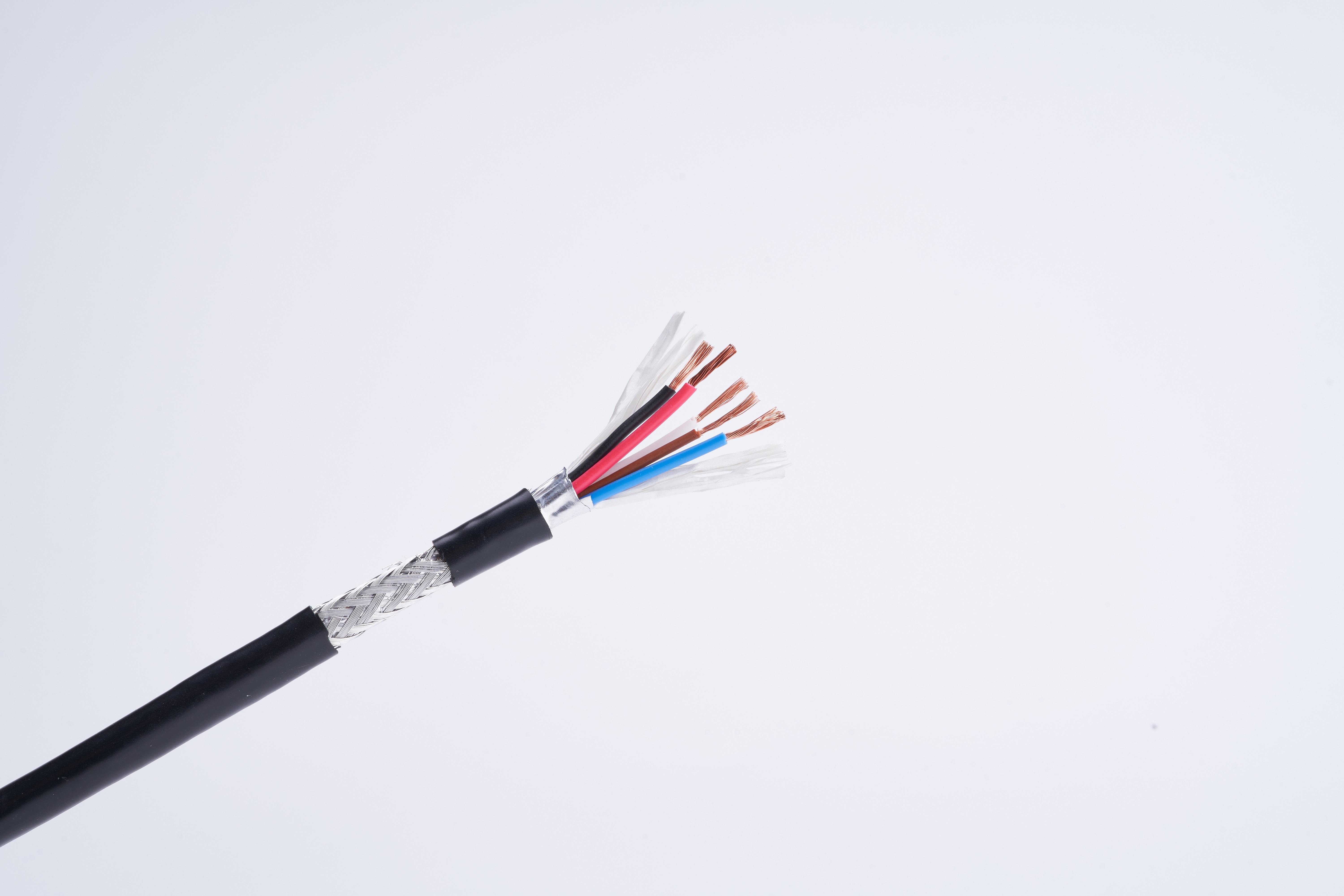

Adopted to industrial and mining enterprises, energy and transportation departments, for AC rated vo...

More details

Adopted to industrial and mining enterprises, energy and transportation departments, for AC rated vo...

More details

Using to connect power amplifier and loudspeaker equipment, broadcast system to transmit audio frequ...

More details

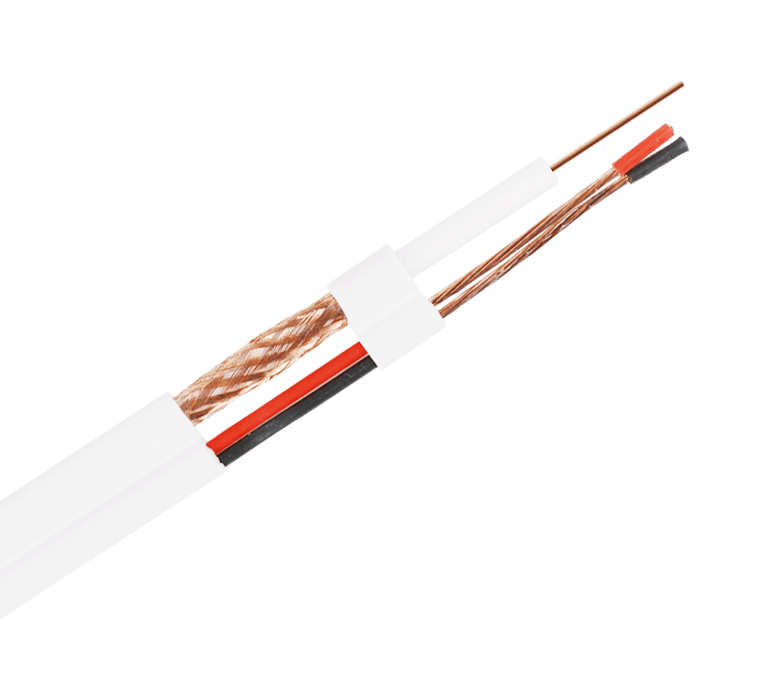

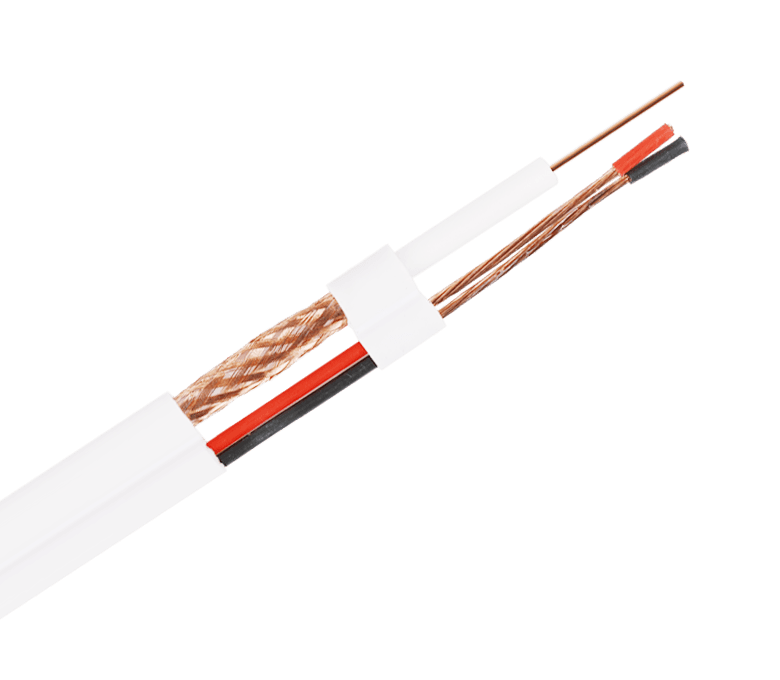

The wire and cable used to connect the security surveillance camera and the real terminal (computer ...

More details

The wire and cable used to connect the security surveillance camera and the real terminal (computer ...

More detailsZhejiang Wanma Tianyi Communication Wire & Cable Co., Ltd. was established in 1992 and is located in Lin'an, Hangzhou, enjoying convenient transportation and beautiful environment. Our company covers an area of 64,000 square meters and has about 800 employees. It is a wholly-owned subsidiary of the national large enterprise, Zhejiang Wanma Co., Ltd., a domestic listed company with stock code: 002276. In 2019, the company was established in Vietnam with a registered capital of 5 million DOLLARS and more than 100 employees.We are professional China Distribution Cable Manufacturers and ODM Distribution Cable factory, offer wholesale Distribution Cable factory for sale at a good price. whose annual output reaches to 1.3 million kilometers, 4 million kilometers' core, 1.5 million boxes and 300,000 kilometers separately. Our products are widely used in smart grids, energy and power, green buildings, smart manufacturing and smart transportation.

Our company has successively passed the certifications of ISO9001, ISO14001 and ISO45001, which is one of Tops in China Electronic Component Industry. It is fostered and supported by Zhejiang Government and plays a leading role in industry. "Tianyi" is assessed as Zhejiang famous brand for many years. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. Upholding the philosophy of "Quality is the life of an enterprise", our company pays high attention to product quality. Therefore, we are equipped with world advanced production equipment and high-precision inspection equipment.

All our products confirm to UL, ETL, RoHS, CPR certification. Selling well in all cities around China, our products are also exported to Europe, Asia, USA and South America. Faced with new opportunities and challenges, we constantly innovate and forge ahead with the corporate culture of "Honest People, Proper Business, Perfect Product". We warmly welcome customers from at home and abroad to cooperate with us for common success.

On June 7, ‘2025 Provincial New Product Appraisal Meeting of Wanma Equipment and Cable’ le...

June Pengcheng, hot when the head, more hot than this industrial exhibition event. 4 June ...

From May 13th to 15th, 2025, the 23rd Interwire exhibition in Atlanta, USA was held in Geo...

2025 The 21st Vietnam (Hanoi) International Industrial Manufacturing & Materials Techn...